The drill rod adopts segmented heat treatment process.

The hardness of the place where the tail of the drill rod contacts with the piston is 45-49 degrees. Because of the material, it is easy to blow the head if it is too high. If it is too low, ① it is easy to drive down the steps that contact with the inner sleeve, which leads to abnormal hammering of the drill rod head when it is too long. ② It is easy to cause the drill rod head to swell.

The hardness of the middle part of the drill rod is generally 30-35 degrees, so the brittleness is relatively less.

The hardness of the tip of the drill rod in contact with the stone is 50-55 degrees, and it can only be invincible when it meets hard stones!

The material of drill rod is generally divided into 40 Cr-Mo and 42 Cr-Mo. However, the comprehensive properties of drill rods, especially the wear resistance, are still very different in different steel mills. You can see how to buy according to your needs.

There are many kinds of tips of drill rods, depending on the working conditions, including round head, pointed head, slotted tip, forging and so on.

Weight of drill rod

Standard length of drill rod

Remember the drill rod price 68-150 75-220 100-380 140-850 155-1500 165-1800 175-2200 185-3100 195-3200 200-3400.

Photovoltaic drill rods can also be customized.

Commonly used rammers are divided into circular disks and square disks, and the dimensions of commonly used square disks are memorized.

45*260 53*260 68*350 70*350 75*350 100*400 140*500

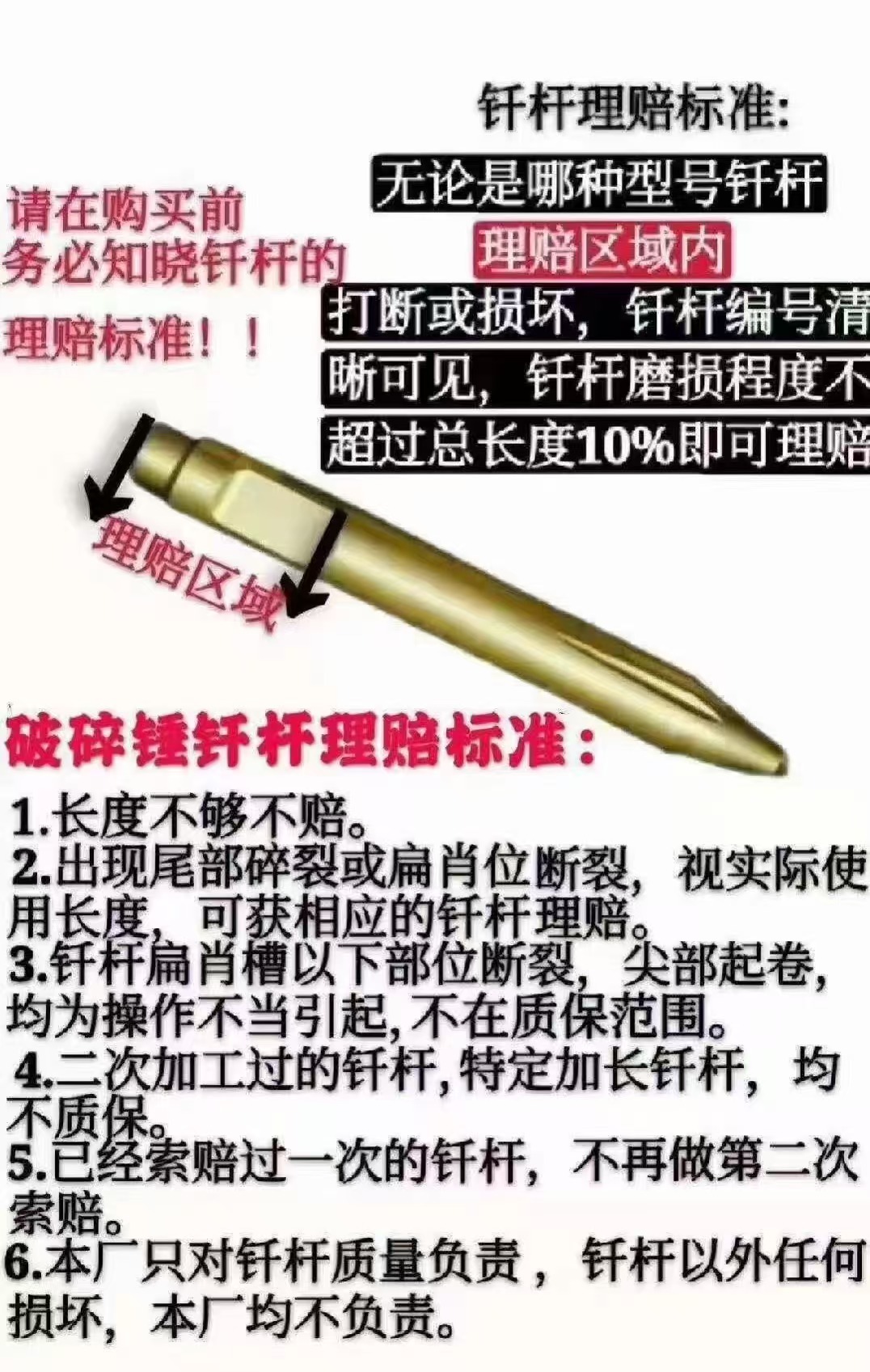

Warranty of rammed solder: The rammed solder is broken, and the warranty period is 1 month. The rammer plate is cracked, and the warranty period is 1 month. If it is detached or broken down, the warranty period is 1 month. If it is welded without permission, there is no warranty period for hitting stones.